|

|

|||||||||||||

|

|

|||||||||||||

|

Beer Bottling Machines

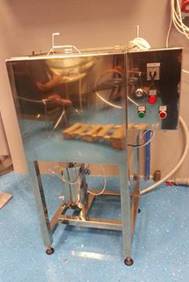

Our Counter Pressure Bottling

Machines are excellent for beer bottling. Foaming-free bottling

requires the product to have a suitable temperature of 2-7 ° C. The bottler

must be able to fill the type of bottle chosen by the customer. Due to their principle

of operation, our counter pressure bottlers are suitable for filling

carbonated products into different types of bottles at pressures up to 4 bar.

The bottler first balances the pressure in his tank and bottle before he

starts gravitationally filling the product into the bottle. The filling level

can be set precisely. When the filling is complete, it releases the excess

pressure from the bottle so that the bottle can be removed from the machine

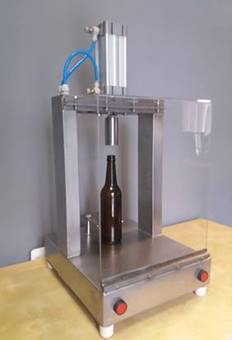

without foaming or with minimal foaming. After filling, the closure is the next step,

which can be done with a screw cap or crown cap. We can offer Screw Cap

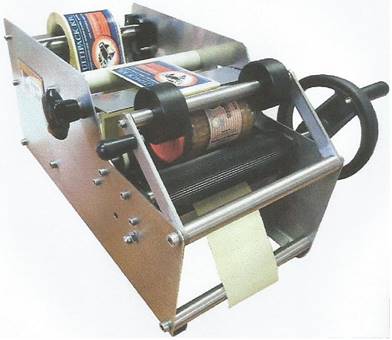

Closing Machine, and Manual Crown Cap Closing Machine. For labeling we can offer a hand-operated Labeling

Machine that can apply self-adhesive labels. Bottles do not always come sterile from the

factory, so a pre-bottling disinfectant rinse may be required, which can be

solved with a dedicated Rinse Machine. Bottle Washer is required for returnable glass bottles. With these machines a complete bottling

plant can be realized. For more information, please click on the pictures

below or contact us.

|

|||||||||||||

|

FALCON

TECHNIKA BT Budapest,

Hungary |

|||||||||||||